Unlocking the Power of a Fabric Label Printer for Business Success

In today's highly competitive market, effective branding and product labeling are critical to gaining consumer trust and standing out on retail shelves. Among the myriad tools available to manufacturers and brands, the fabric label printer has emerged as an indispensable asset for elevating product presentation, ensuring durability, and enhancing operational efficiency. This comprehensive guide explores how integrating a fabric label printer into your business infrastructure can dramatically boost your branding potential, streamline production, and add value to your products.

Why a Fabric Label Printer is Essential for Modern Businesses

The evolution of printing technology has opened countless avenues for businesses to innovate their labeling processes. Unlike traditional paper labels, fabric labels offer a sophisticated, premium look that resonates with consumers seeking quality and authenticity. A fabric label printer specializes in creating high-resolution, durable labels that withstand harsh conditions—such as washing, abrasion, and exposure to sunlight—making them ideal for textiles, apparel, and other soft goods.

Key advantages of using a fabric label printer include:

- Enhanced Brand Image: Fabric labels convey a sense of luxury and authenticity, making your products more appealing and trustworthy.

- Customization & Flexibility: Create various designs, sizes, and shapes tailored for different products and markets.

- Durability & Longevity: Fabric labels designed with a fabric label printer resist fading, peeling, or fraying over time.

- Cost Efficiency: Reduce overhead by printing labels on-demand, minimizing waste and inventory.

- Rapid Production Cycles: Switch between designs swiftly, enabling quick response to market trends or seasonal releases.

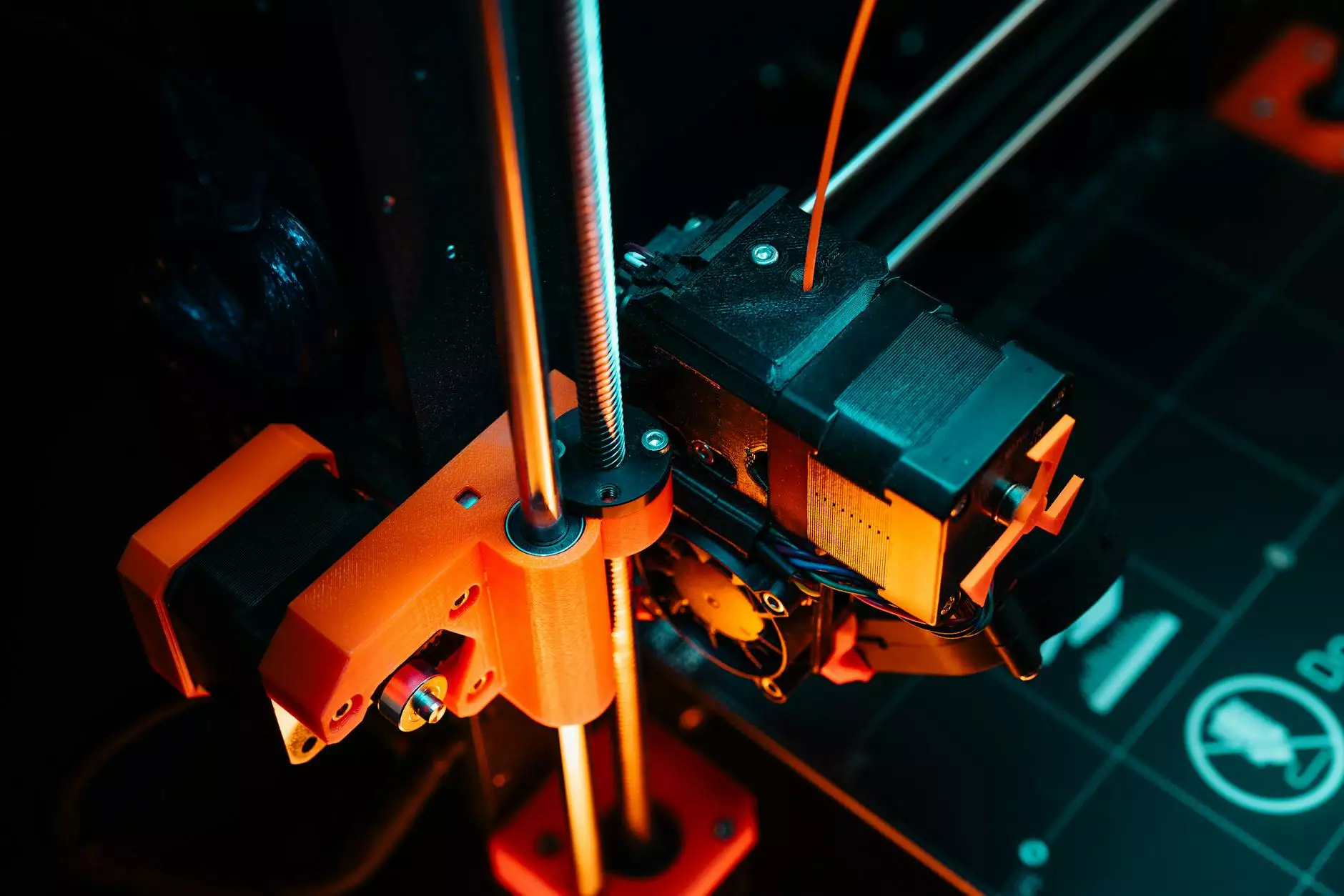

The Technology Behind a Fabric Label Printer

Modern fabric label printers employ advanced digital printing technologies, predominantly dye sublimation, heat transfer, and direct-to-fabric (DTF) printing. Each method offers distinct benefits aligned with different business needs.

1. Dye Sublimation Printing

Dye sublimation is renowned for producing vibrant, full-color images directly onto fabric substrates that are coated with polyester. The process involves printing dye onto a transfer paper and then applying heat and pressure to embed the ink into the fabric, resulting in a seamless, durable label that resists washing and fading.

2. Heat Transfer Printing

Heat transfer techniques involve printing designs onto special transfer paper, which is then heat-pressed onto fabric labels. This method allows for sharp images and detailed graphics, making it suitable for intricate branding elements or small batch runs.

3. Direct-to-Fabric (DTF) Printing

DTF technology involves printing directly onto fabric fibers, offering high-speed production with excellent durability and vibrancy. It is especially effective for custom orders and short runs, providing flexibility without sacrificing quality.

The choice of technology depends on your business size, target market, budget, and product specifications. However, investing in a high-caliber fabric label printer ensures your labels are both visually appealing and industrially robust.

Key Features to Look for in a High-Quality Fabric Label Printer

Not all fabric label printers are created equal. To maximize your investment, consider the following essential features:

- Resolution & Image Quality: High DPI (dots per inch) ensures crisp, detailed images and text.

- Color Range & Reproduction: Wide gamut for vibrant, accurate colors that match your branding palette.

- Print Speed & Efficiency: Faster output capabilities minimize lead times and increase productivity.

- Durability & Resistance: The ability to produce labels that withstand multiple washes, UV exposure, and friction.

- Ease of Use & Maintenance: User-friendly interfaces and low-maintenance features save time and operational costs.

- Compatibility & Connectivity: Support for various file formats, wireless options, and integration with design software.

- Cost of Operation: Low ink or consumable costs and energy efficiency reduce overall expenses.

The Role of Electronics & Innovation in Modern Fabric Label Printing

The evolution of electronic components and digital controls has significantly enhanced the capabilities of fabric label printers. Cutting-edge electronics enable precise regulation of printing parameters, temperature control, and color fidelity, ensuring consistent quality across all labels produced.

Recent innovations include QR code integration, RFID labeling, and smart automation features that streamline batch processing and inventory management. These advancements allow brands to incorporate traceability, authenticity verification, and interactive branding directly into their fabric labels, elevating consumer experience and trust.

Implementing a Fabric Label Printer in Your Business: Practical Considerations

Capacity & Scalability

Understand your current production volume and future growth projections. Select a fabric label printer that can scale with your business, offering higher throughput and suitable for varying order sizes.

Material Compatibility

Ensure the printer supports a range of fabric types, such as polyester, cotton, or blended materials. Versatility is crucial for producing labels tailored to different products.

Design Flexibility & Software Integration

Opt for printers that come with intuitive design software or seamless integration with popular graphic programs. This leads to smoother workflows and more creative freedom.

Cost & Return on Investment

Calculate upfront costs versus long-term savings through reduced outsourcing, decreased waste, and faster turnaround times. A high-quality fabric label printer is an investment that can dramatically improve your operational efficiency and brand perception.

How DurafastLabel Leads the Industry in Fabric Label Printing Solutions

At durafastlabel.com, we specialize in providing top-tier fabric label printer solutions that cater to a diverse range of business needs. Our commitment to quality, innovation, and customer satisfaction positions us as a leader in the printing services and electronics sectors.

Our cutting-edge technology encompasses the latest in dye sublimation, heat transfer, and direct-to-fabric printing, ensuring that your labels are of exemplary quality and durability. With our dedicated support, comprehensive training, and customized solutions, you can confidently integrate a fabric label printer into your operations.

Moreover, our focus on sustainable practices and eco-friendly inks ensures you can produce high-quality labels while minimizing environmental impact—aligning your brand with modern consumer values.

Conclusion: Elevate Your Business with a Fabric Label Printer

Whether you're a small startup or an established manufacturer, investing in a fabric label printer unlocks countless opportunities for branding, quality improvement, and operational excellence. From creating durable labels that withstand the rigors of washing to offering vibrant, customizable designs that captivate consumers, the benefits are profound.

Embrace innovation, leverage advanced electronics, and partner with industry leaders like DurafastLabel to propel your business forward. In a marketplace where branding and product presentation can make all the difference, the right fabric label printer is your key to success.